How much does it cost to repair a commercial espresso machine?

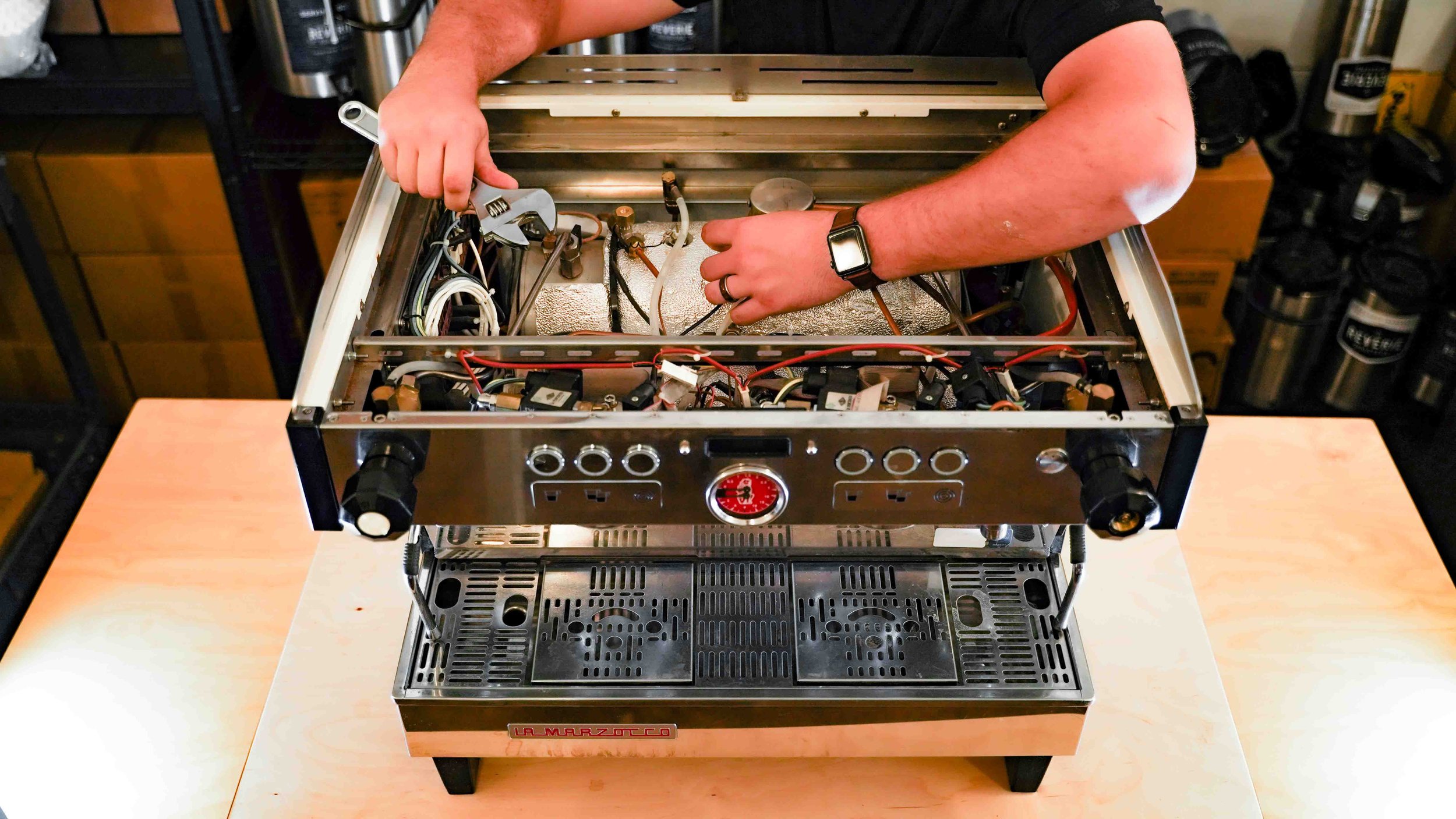

Looking inside the top of a La Marzocco 2-Group ABR espresso machine. We sell and repair these machines.

Repairing commercial espresso machines is a very difficult thing to estimate because of many factors. Your equipment will need repairs from time to time. This is normal. You use this machine to do tasks that ultimately generate revenue. It’s not practical to think they won’t need fixing from time to time. Here’s a list of considerations for when you are looking at estimating the cost for repairing your equipment.

Diagnosing the Whole Issue – Most symptoms of a problematic machine are a signal that something else may also need fixed. A slow drip of water may point to a minor gasket cleaning or repair, but the real issue may be water quality. Not powering up may signal an issue with the electrical board, but it may be pointing to a short caused by corrosion (again, a water quality issue…beginning to see a theme here?) When you find an issue to call a service tech, take note of all you know isn’t working correctly. Low flow rate, slow to heat up, drips and sounds, and more.

Equipment Brand and Availability of Parts – Depending on where your business resides will sometimes determine the availability of parts and qualified service technicians available to service your equipment needs. There tends to be more parts and techs available for coffee equipment manufacturers based on what brands have historically sold in your region. In Middle America, we see espresso machine brands such as La Marzocco, Nuova Simonelli, UNIC, Franke Systems & Eversys. Time is money when it comes to machines going down even for a day. The sooner you get your equipment repaired the better, even if it may cost more per hour for quality service or a tech that will work at overtime rates to get you up and running.

Technician Experience – The coffee equipment vocation is very niche, having the demand for technicians to have experience in three types of systems: electrical, water and mechanical. And while technicians can get formal training by the manufacturers and some short certification programs, most of the experience of coffee equipment tech comes from simply doing the work. A seasoned technician may be more costly per hour, but they could save money in the short term with quick diagnosis and repair, or by fixing other issues that may creep up in the future.

Flexibility in Schedule – Equipment technicians are busy humans with customers and families outside work. If you demand they come during closing hours, you can expect to pay 150% of the normal rate. Being flexible to take them in when they are first available may be a little cheaper and a little less stressful for the tech who isn’t working beyond their normal 8-hour workday.

These are just a few quick considerations for when you are costing out a repair project. The only way to get a real quote is to have a coffee technician observe the equipment in person. They are trained to observe as much visually as possible. They will run the machine and tests to give their best guess as to what the solution will be. While they can offer a quote, it is not uncommon they may find other issues. As mentioned in the beginning of the article, what you see as the issue is normally a symptom. It is common for customers to feel like techs overcharge for the repairs without understanding there may be other problems to discover. And this is certainly why it’s important to provide as much info as possible and ask for the tech to check it out in person.

Cost Per Hour – Espresso machine repair technicians charge standards rates of between $100 and $150 per hour and between $150 to $225 per hour for overtime (if rushed, or, outside normal business hours). Small jobs can take as little as an hour or two to diagnose and make small repairs on-site. If your repair requires ordering special parts or items that are not in stock, you can expect to have a second call to finalize repairs. For repairs that require the removal of the machine from your site for off-site repairs, like in the instance of a more comprehensive restoration, you can expect the tech to work on your equipment in their spare time between calls to prioritize emergencies. The rates are generally the same. IN the event your machine is removed, you will possibly need a loaner machine. Your tech can get your second machine setup, or in some rare cases, they can offer you a loaner machine to get buy for a week or two at a time. Rates for loaner machines can cost between $25 and $75 per day.

Cost of Parts – Espresso technicians purchase and resell parts as part of their business plan. They purchase parts at a discount and mark them up to cover their operating and inventory costs. Some technicians will allow you to buy your own parts and install them for you. You don’t always get a discount on parts like repair technicians and may not save any money. And the tech may not be able to warranty the part if they did not purchase it originally. Be sure to ask your tech what you are allowed to do before assuming they will install other parts. Parts can be as low as a few dollars for O-Rings and other small fittings. Boilers and more expensive parts can cost hundreds to thousands of dollars. Ask your tech to estimate or quote you on the price of the repair and parts costs before agreeing to go with the repairs.

Are Discounts Available – Some repair customers are eligible for discounts on their service and parts for being customers to the coffee technician’s partner company. For example, Reverie Coffee Roasters’ customers enjoy discounts on equipment service for simply being a coffee customer. Our service company, Principal Coffee Equipment Solutions, offers subscription agreements for maintenance services that come with discounts on parts and labor.

Role of Preventative Maintenance – Preventative Maintenance (PM) is one of the most crucial components of successful ownership of coffee equipment. Every equipment manufacturer has a scheduled list for repairs every year. Qualified service technicians can pre-schedule your quarterly, semi-annual and annual maintenance. This will include cleaning and rebuilding of parts that goes beyond what your team is required to clean every day at the end of the business day. They can also take this time to replace water filters. Depending on the cycle for repair you may experience more comprehensive PM’s. For example, in the 2nd or 3rd year of a machine’s life it may be recommended to replace a few parts that are designed for safety. Neglecting these recommended repairs puts the machine’s longevity into question and can potentially cause undue harm to your staff, equipment, and the business property. We would never recommend skipping your equipment PM.

Best Practices – Great water filtration that is up to the standards set by your coffee equipment is the best way to prevent issues with your equipment. Reverse Osmosis (R/O) systems with re-mineralization is the most common in Middle America to protect equipment and to make great tasting coffee. Ask your coffee roaster or equipment dealer what they recommend. You must protect your equipment daily by performing the standard cleaning procedures set by the manufacturer. Your tech can show you the best way to clean the machine, which includes backflushing the machine, cleaning the screens, soaking the steam wands, and more. If you are concerned your staff is cutting short their obligation to clean this extremely expensive equipment each day, your tech can show you ways to identify neglect. And if you don’t value clean equipment, your team probably won’t, and you can expect more frequent visits by the service tech.

Are you getting the best care for your equipment? Do you want to know about how our service company, Principal Coffee Equipment Solutions, handles coffee equipment for its customers?

Head over to their page HERE or call us at (316) 393-8877.